A 40 YEAR JOURNEY IN SOUND AND TECHNOLOGY

From its backyard origins building loudspeakers, Arvus has continually reached beyond boundaries,

expanding into digital cinema, amplifiers, projection screens and onto

nuclear and geothermal energy, maglev solutions, digital audio converters

and multi-national mega-projects.

expanding into digital cinema, amplifiers, projection screens and onto

nuclear and geothermal energy, maglev solutions, digital audio converters

and multi-national mega-projects.

1983 - 1989 A schoolboy's passion

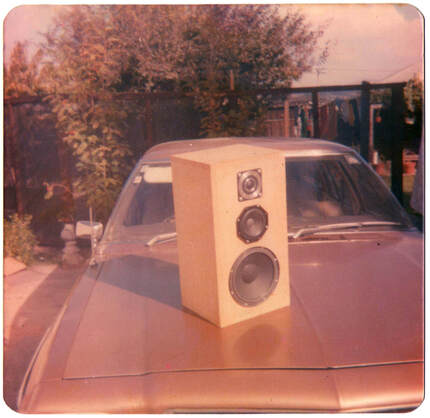

1983 - Matthew A. Simmons officially started what was to evolve into Arvus International Limited when he was a 12 year-old boy using his father’s converted photography darkroom as a workshop. Back then his business activity was repairing speakers. He would pick them up on his bicycle after school from businesses throughout Christchurch, New Zealand and work on them in the evenings and weekends. He also started to build his own speakers.

1983 - Matthew A. Simmons officially started what was to evolve into Arvus International Limited when he was a 12 year-old boy using his father’s converted photography darkroom as a workshop. Back then his business activity was repairing speakers. He would pick them up on his bicycle after school from businesses throughout Christchurch, New Zealand and work on them in the evenings and weekends. He also started to build his own speakers.

1987 - Matthew contracted a near fatal virus and spent many months in hospital. During his two-year convalescence Matthew read countless biographies of artists, inventors, and world leaders, which greatly inspired him. He also managed to continue repairing speakers to pay for his book and compact disc consumption.

1989 - In the the last year of his schooling, Matthew managed to build up his little business, then called Encore Audio, to be servicing 40+ firms. He was already making and selling custom designed loudspeakers using heavily modified off-the shelf drivers. He sold many to his trusting school teachers.

1990 – 1993 Failure to launch

Matthew left home to study music composition at Otago University, producing many original pieces of electronic music. He also rented studios around Dunedin and continued to repair and build speakers.

1991 - After his first year, Matthew left university to launch a unique loudspeaker product made from PVC pipes. He sold most of his possessions to finance the venture, and traveled from the bottom to the top of New Zealand with two pairs of his new speakers in the boot of his Triumph 2000, visiting dozens of Hi-Fi shops on the way to get interest in his new product.

Matthew left home to study music composition at Otago University, producing many original pieces of electronic music. He also rented studios around Dunedin and continued to repair and build speakers.

1991 - After his first year, Matthew left university to launch a unique loudspeaker product made from PVC pipes. He sold most of his possessions to finance the venture, and traveled from the bottom to the top of New Zealand with two pairs of his new speakers in the boot of his Triumph 2000, visiting dozens of Hi-Fi shops on the way to get interest in his new product.

He failed spectacularly! Unable to raise any interest in his hand made speakers, Matthew decided to get a job at the local record shop to pay off his year of accumulated bills.

1994 – 1998 Taking business seriously

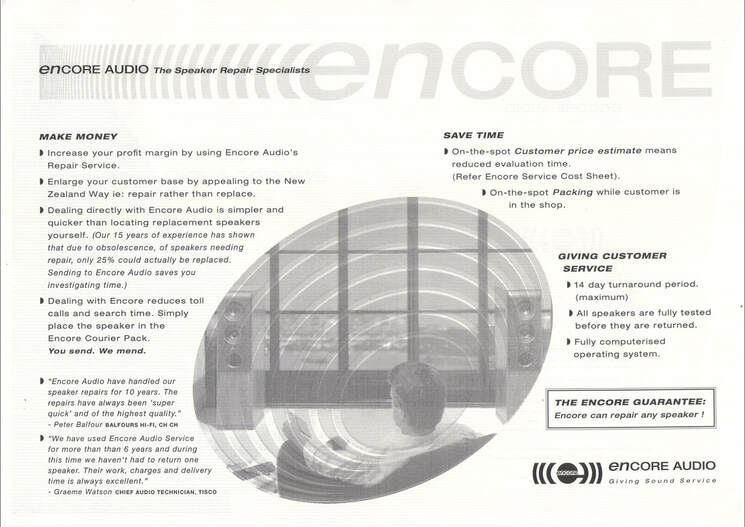

Now back in Christchurch and married with children on the way, Matthew wanted to expand his little speaker repair business. His big brother Mark helped him develop a full business plan and a branding exercise. By the end of 1995, Encore Audio was repairing hundreds of loudspeakers a month and hiring contractors to cope with the increasing work.

1994 – 1998 Taking business seriously

Now back in Christchurch and married with children on the way, Matthew wanted to expand his little speaker repair business. His big brother Mark helped him develop a full business plan and a branding exercise. By the end of 1995, Encore Audio was repairing hundreds of loudspeakers a month and hiring contractors to cope with the increasing work.

It was also over this period that Matthew was formulating his own theories on loudspeakers and investing heavily in countless prototypes.

1997 – Matthew was approached by a successful businessman and engineer to help him bring an innovative loudspeaker design to reality.

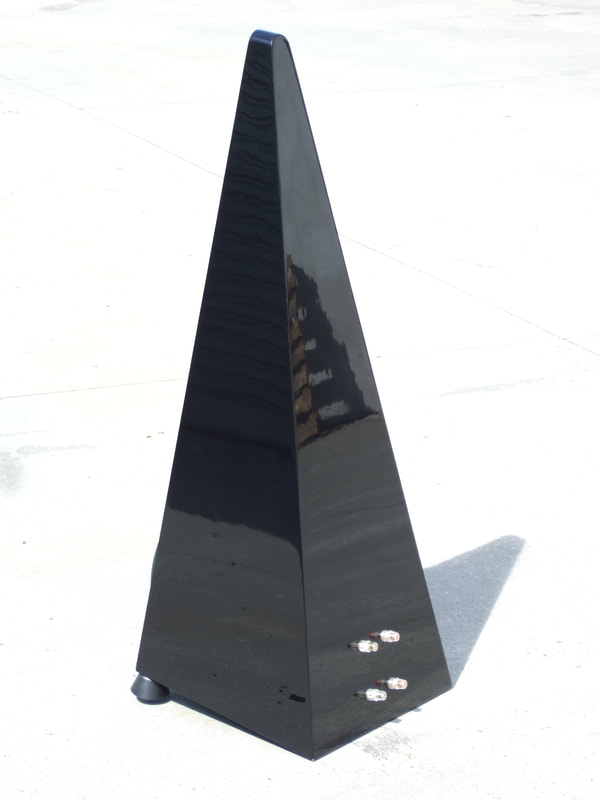

A 'tour de force' of engineering, and with a sound much larger than its size, the Environ was an amazing accomplishment. Sadly it was just too costly to make, and thus only 20 pairs were sold. The Sphear Environ took 5 years to develop. However, the many engineering processes that Matthew learned on this project ignited a wider interest in engineering, material science and manufacturing.

1997 - Matthew felt he needed a new brand so he could sell more speakers. Looking at his Audi Avus photo (which hung above his studio desk) he was inspired by the Avus name and the font used. He added the R plus a 'braun-esque' treatment to the V and the Arvus brand was born.

1998 - QS-5 was the first true 'production' speaker under the Arvus brand. It sold more than 100 pair in 11 months. This hand-made speaker funded much initial Arvus research and development in loudspeakers. The 5" driver was designed in house, required no low-pass crossover and had a unique magnet structure developed and manufactured by Arvus which eliminated almost all distortion-causing eddy currents.

1999 - 2002 Arvus evolves

Arvus Loudspeakers really came alive in 1999. In the ensuing four years almost 500 pairs of Arvus speakers were sold, via the internet and through referrals, in over 20 countries. With no reviews or magazine advertising, all the sales were direct. Arvus explored and made dozens of designs. All the raw speakers (woofers and tweeters) were either custom designed and manufactured offshore or hand-built in their small Christchurch based workshop.

Arvus Loudspeakers really came alive in 1999. In the ensuing four years almost 500 pairs of Arvus speakers were sold, via the internet and through referrals, in over 20 countries. With no reviews or magazine advertising, all the sales were direct. Arvus explored and made dozens of designs. All the raw speakers (woofers and tweeters) were either custom designed and manufactured offshore or hand-built in their small Christchurch based workshop.

2001 - Arvus Loudspeakers presented itself to the Public for the first time at the ‘Big Boys Toys’ show in Auckland. Here Arvus demonstrated the grandeur of the Proscenium and the power of the insane 250Kg, 2M high Bladderbuster subwoofer.

2003 - 2007 Digital cinema and beyond

2003 - Arvus was contacted by a large US-based organization to do an acoustic development contract. After a few short weeks the organization retracted the contract as its needs changed, but Matthew decided to keep the development going as this new field of Infrasound acoustics intrigued him. The TedX talk is about this story.

2003 - Arvus was contacted by a large US-based organization to do an acoustic development contract. After a few short weeks the organization retracted the contract as its needs changed, but Matthew decided to keep the development going as this new field of Infrasound acoustics intrigued him. The TedX talk is about this story.

2003 - As the DVD/Home theatre market was becoming increasingly crowded, Arvus pivoted to Digital Cinema on the hunch that the industry would need a marketable point of difference from Home Theatre. From this decision was born the move for Arvus to develop the Hypacoustic™ cinema brand.

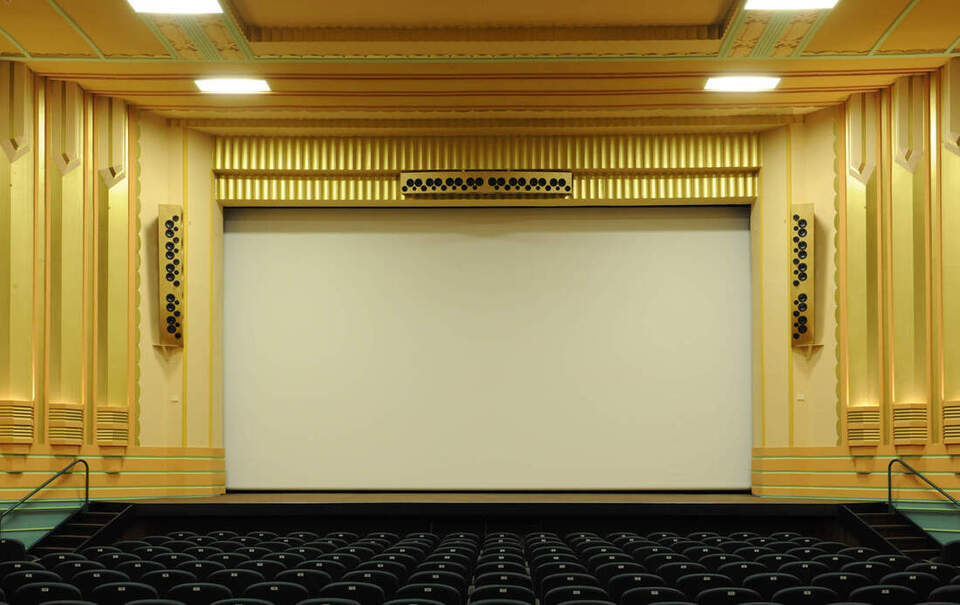

2003 - The first cinema contract was also completed for Regent Ashburton.

2003 - Theophany founder contacted Arvus to supply some raw loudspeaker drivers. In the ensuing eight years, Theophany established its brand, international sales, and built a factory to cope with growth. Arvus supplied their unique technology to Theophany from 2003 to 2010.

2004 - Arvus designed a custom turbo inter-cooler using peltier devices. It worked so well that Matthew believed solid-state power generation would have huge potential for future energy applications if more efficient solutions were developed. He committed himself to a personal long-term research path into solid-state materials and phenomena, culminating 15 years later in the US based company Stargena, which Matthew co-founded in 2020.

2004 - Arvus supplied a complete audio system for a twin-plex cinema for Jim Marron, the founder of Electric Lady Studios (Jimi Hendrix, Eagles, Stevie Wonder).

2005 - After three years of development the Arvus flagship product the Horizon was completed. This 5-way speaker used only fully-designed and manufactured drivers, including Arvus Annular tweeters. The Horizon was also the first product to benefit the work Arvus was doing in psycho-acoustics, as the product changed its frequency response depending on input level.

2003 - Theophany founder contacted Arvus to supply some raw loudspeaker drivers. In the ensuing eight years, Theophany established its brand, international sales, and built a factory to cope with growth. Arvus supplied their unique technology to Theophany from 2003 to 2010.

2004 - Arvus designed a custom turbo inter-cooler using peltier devices. It worked so well that Matthew believed solid-state power generation would have huge potential for future energy applications if more efficient solutions were developed. He committed himself to a personal long-term research path into solid-state materials and phenomena, culminating 15 years later in the US based company Stargena, which Matthew co-founded in 2020.

2004 - Arvus supplied a complete audio system for a twin-plex cinema for Jim Marron, the founder of Electric Lady Studios (Jimi Hendrix, Eagles, Stevie Wonder).

2005 - After three years of development the Arvus flagship product the Horizon was completed. This 5-way speaker used only fully-designed and manufactured drivers, including Arvus Annular tweeters. The Horizon was also the first product to benefit the work Arvus was doing in psycho-acoustics, as the product changed its frequency response depending on input level.

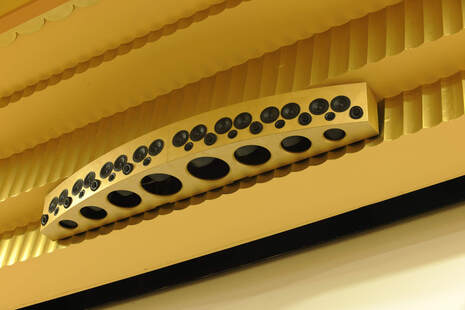

2006 - At the same time, Arvus was contracted to develop and supply the world’s first onboard karaoke system for an amusement ride vehicle, for the Wiggles Big Red Car ride in Dreamworld, Gold Coast, Australia. Special microphones had to be developed so that there was no feedback from the speakers directly next them.

2006 - In September the first official Hypacoustic cinema "Valhalla" opened. Though this cinema preceded Dolby Atmos® by almost 5 years, it was actually one of the first digital cinemas in the world with ceiling speakers and real-time processing used for the twin 'height' channels.

2006 - With the increasing success of their Hypacoustic cinemas, Arvus saw an opportunity to develop high-contrast projection screens and thus Hypascreen™ development started.

Fully developed in New Zealand, the screen formulation was a special combination of 27 materials and metals crushed to a very exactly particle size. This mixture was then powder-coated onto an aluminium laminate. A custom aluminium extrusion was developed for the frame. The Hypascreens were one of Arvus' most successful products with units sold all over the globe for many years. Once LED panels became cost effective the sales of Hypascreens dropped off significantly.

2006 - Arvus' first foray into building amplifiers, the "Glide,” was completed. Arvus subsequently built dozens of home audio and pro-cinema amplifiers utilizing IcePower™ modules until 2011.

2007 - By the end of the year four, Cinemas had been converted to Hypacoustic™ in Australia.

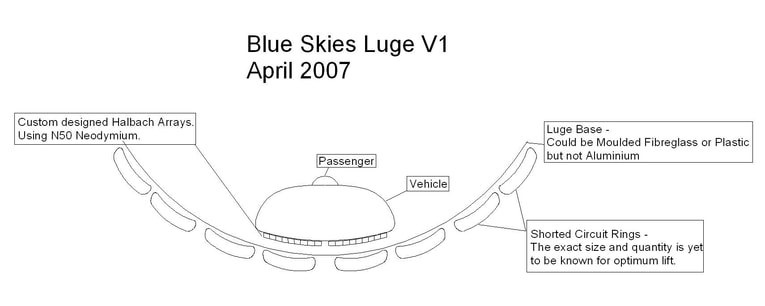

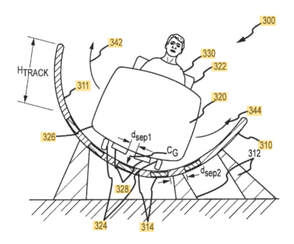

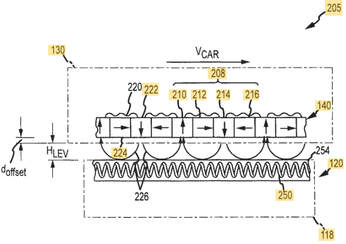

2007 - Imagineering contracted Arvus for blue skies research as part of a small New Zealand based team. Arvus proposed the concept of a magnetic levitation luge for a future ride based on its prior work for Halbach arrays. Impressed by the concept, Disney decided to patent the design worldwide, with all three noted on the Patent.

2007 - In November Arvus installed its first 5m wide solid all-weather Hypascreen. This product used a variant of powder coating developed for indoor use as it had a higher light gain and contrast ratios. Fully designed and manufactured by Arvus using high grade aluminium, this solution was also designed to withstand very high winds and earthquakes. After the many earthquakes of 2010-2012, the screen was still securely mounted in its original location.

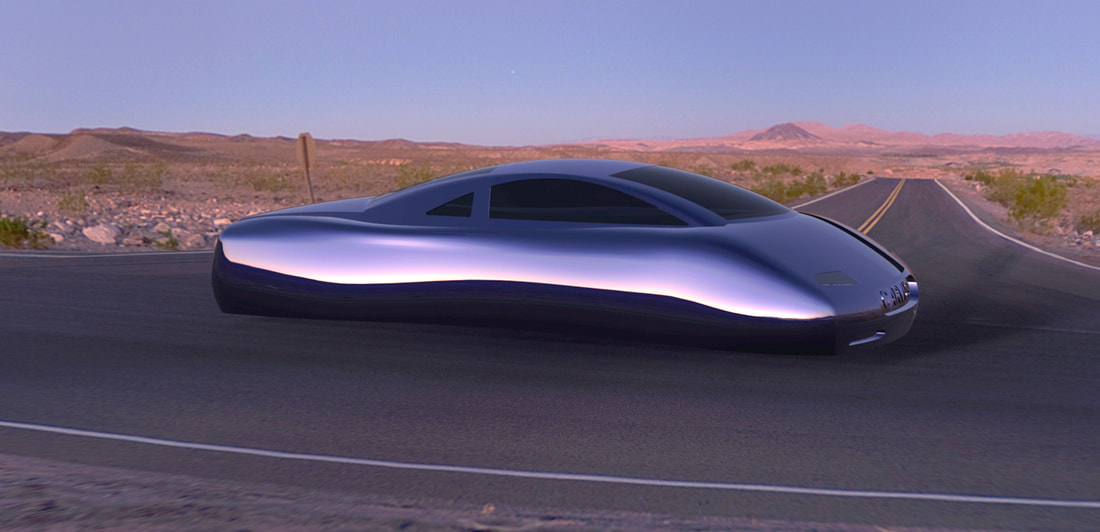

2007 - December, Arvus became a major sponsor of the New Zealand Solar car project, SolarFern. The design used some world-unique active aerodynamic technology which, when the wind & thermal conditions were right, enabled the car to speed along the landscape using almost no electricity.

2008 Celebrating 25 years in business

To celebrate 25 years of loudspeaker development, Arvus released the USD140k flagship and technology showcase the 'Prerenaissance'.

To celebrate 25 years of loudspeaker development, Arvus released the USD140k flagship and technology showcase the 'Prerenaissance'.

2008 - Arvus installed a Twin-Bladderbuster Hypacoustic cinema system in one of Kodak’s screening rooms at Laser Pacific. In the subsequent three years, dozens of Hollywood films were edited and produced using this Hypacoustic™ installation.

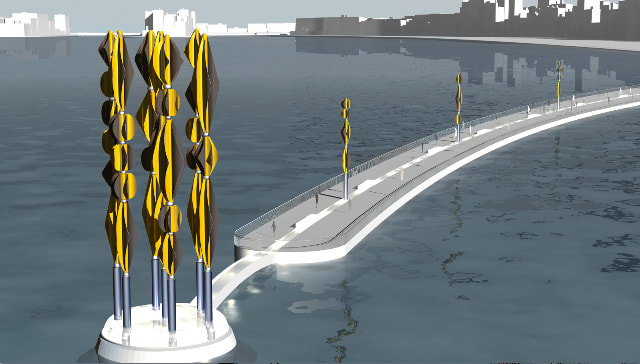

2008 - Arvus and Design Energy partnered up to develop custom electric motors and a grid-tied power system for a high profile wind-farm project in Dubai. This visionary project was the brainchild of master New Zealand Sculptor Andrew Drummond. Though funding was secured and the NZ Government agreed to support the project, the collapse of Lehman Brothers and the ensuing Global Financial Crisis caused the multi-million dollar project to be shelved.

2009 - 2011 Hypacoustic, Hypascreen, earthquakes and relocation

2009 - A Hypacoustic™ cinema system was installed in the British Film Institute. This successful demonstration system took two years from concept to final installation and was the critical milestone that cause adoption of the technology in Russia, India, China and Australia.

2009 - A Hypacoustic™ cinema system was installed in the British Film Institute. This successful demonstration system took two years from concept to final installation and was the critical milestone that cause adoption of the technology in Russia, India, China and Australia.

2009 - Dolby contracted Arvus to design and supply 27 customer loudspeakers as a platform for the experimental work they were doing in 3-D sound. This new object-based audio technology became Dolby Atmos®, and the project marked the start of the long-term relationship between the two companies.

2009 - Inspired by what he learned from the Solarfern team, Matthew explored a few electric car designs with many of his engineers in group 'think tanks'. The culmination of these explorations was the Carvus. Though never fully realised the project taught Matthew the value of power efficiency, knowledge he would carry on in his future ventures.

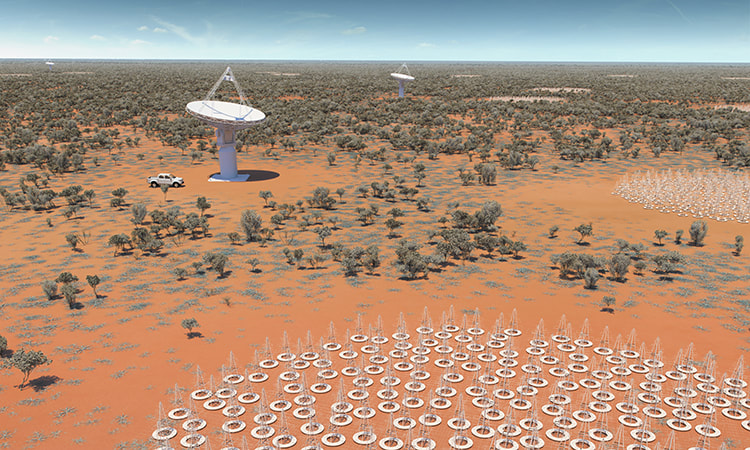

2009 - Arvus was invited by the NZ Government to discuss becoming a possible resource for NZ's future involvement in the very large radio telescope project called the Square Kilometre Array. This hundred-year project got Matthew and the Arvus engineers very excited about the scale, challenges and potential impact of the project. The Arvus team agreed to support the NZ Government and explore technical opportunities. This decision led to what would become Nyriad in 2015.

2010 - After many trips to China and Hong Kong, Hypacoustic won a contract in May 2010 to supply up to 400+ audio systems to the fast-growing Chinese cinema company Lumiere Pavilions.

2010 - Arvus was asked to design and supply custom speakers for Dolby Australia for the development of their VoIP conference phone system.

2010 - In August Arvus was contracted to supply their DualView™ Hypascreens for the headquarters of Singtel in Singapore. Twenty screens were placed in a circle with twenty projectors in a central cluster, projecting out to the inside of the screens. The unique panels developed by Arvus enabled an equal brightness of image on the inside and outside, regardless of which surface the image is projected onto.

2010 - Due to a challenge with a digital audio interface in their Hypacoustic systems in China, Arvus urgently designed, developed and deployed their 8-channel AES/EBU to HDMI Audio interface in a matter of weeks, and launched their journey into digital audio.

2010 - Four Hypacoustic systems for Nova Cinemas in Melbourne, Australia were completed in July. All used a new surround design inspired by the pipe speakers developed back in 1991.

2010 - In August the largest Hypacoustic cinema in the world was completed, and sadly after 150+ cinemas it was also the last. The triple-plex in Grafton, Australia is a fully restored art deco 1200 seat sinema and two 180 seat cinemas, called the Saraton. This project spanned 5 years and was the most complex and difficult audio system Arvus engineers had done to date. Arvus developed custom driver technology with four voice coils per 5" speaker, ultra high impedance drivers (128 ohms), custom front speakers, surrounds, amplifiers and infrasound technology to shake the very large cinema.

2010 - On September 4, at 4.34 am Christchurch suffered a 7.1 Earthquake. Over the following months the thousands of aftershocks effected hundreds of thousands lives, and changed the city forever.

2011 - On February 22, 2011 an extremely violent 6.3 aftershock struck at 12.21pm. It was recorded as having the fastest rate of ground acceleration of any recorded earthquake – 2.2g’s. More than 180 people were killed in the quake.

Arvus as it was with studios, research and manufacturing facilities was ended by this tragic quake. Staff left Christchurch and Arvus was unable to complete the large contract for Lumiere Pavilions, as only 21 of the 400+ cinemas were completed. Arvus quickly transitioned from being a profitable business to a debt-laden company with no income in a matter of months. Matthew and his wife relocated their family to Taupo, North Island to start again. Now in a new city, Matthew chose to slowly pay the debts back rather than declare bankruptcy. He set up a new company so the Arvus brand could continue.

Arvus as it was with studios, research and manufacturing facilities was ended by this tragic quake. Staff left Christchurch and Arvus was unable to complete the large contract for Lumiere Pavilions, as only 21 of the 400+ cinemas were completed. Arvus quickly transitioned from being a profitable business to a debt-laden company with no income in a matter of months. Matthew and his wife relocated their family to Taupo, North Island to start again. Now in a new city, Matthew chose to slowly pay the debts back rather than declare bankruptcy. He set up a new company so the Arvus brand could continue.

2011 - In September, Sony Entertainment contacted Arvus to complete development of their 8 channel HDMI to AES/EBU converter. Matthew designed the solution and identified various contractors to manufacture and assemble the product. Though it took longer than estimated, the first 20 units were supplied and within a year the HDMI-2A becomes industry standard for all XBox and PlayStation game developers.

2012 Nuclear and geothermal energy

Over the years Arvus had garnered the respect of the New Zealand government, and so when Arvus relocated to Taupo (the national hub of geothermal energy) Matthew was asked to be CEO of the New Zealand Clean Energy Centre for a nine-month transitional position. Over this period he became immersed in all aspects of clean-tech, and had the opportunity to host many international delegations. All the while, he was listening and learning from the energy sector's challenges and opportunities. Matthew and his core team of international engineers evolved into a significant think tank, committing to a long-term strategy to become involved in the energy sector.

2012 - In May, Matthew was contracted to perform a due diligence project on the possible opportunities of investing in Thorium reactor technology. The intense multi-month project revealed many advantages of the molten-salt Thorium reactor designs. He interacted with influential companies and individuals in this emerging industry and made many new friends. Although the primary investor ultimately decided not to pursue the Thorium opportunities, Matthew and his team remained engaged in the associated technological development.

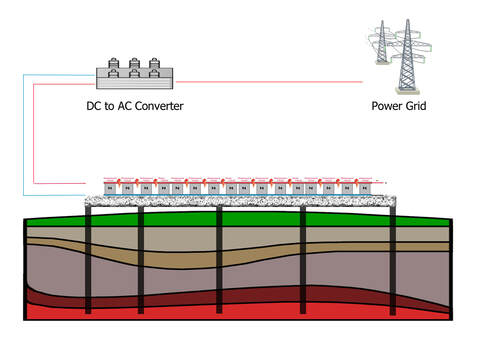

2012 - In June Matthew designed a solid-state geothermal plant using special heat transfer rods that he discovered as part of his Thorium research. He called the solution Thermagenz and decided to explore the opportunity.

Over the years Arvus had garnered the respect of the New Zealand government, and so when Arvus relocated to Taupo (the national hub of geothermal energy) Matthew was asked to be CEO of the New Zealand Clean Energy Centre for a nine-month transitional position. Over this period he became immersed in all aspects of clean-tech, and had the opportunity to host many international delegations. All the while, he was listening and learning from the energy sector's challenges and opportunities. Matthew and his core team of international engineers evolved into a significant think tank, committing to a long-term strategy to become involved in the energy sector.

2012 - In May, Matthew was contracted to perform a due diligence project on the possible opportunities of investing in Thorium reactor technology. The intense multi-month project revealed many advantages of the molten-salt Thorium reactor designs. He interacted with influential companies and individuals in this emerging industry and made many new friends. Although the primary investor ultimately decided not to pursue the Thorium opportunities, Matthew and his team remained engaged in the associated technological development.

2012 - In June Matthew designed a solid-state geothermal plant using special heat transfer rods that he discovered as part of his Thorium research. He called the solution Thermagenz and decided to explore the opportunity.

2012 - In July initial work started on a solid-state thermal extraction solution for vitrified nuclear waste. Though this technology did not eventually go into production, many of the insights were later applied to the Stargena technology mentioned below

2012 - Matthew travelled to Europe (Portugal, UK and Netherlands) and represented New Zealand at the International Power Conference for the Square Kilometer Array project.

2012 - Matthew lead the founding of New Zealand Extreme Materials Initiative (NZEMI) in September with dozens of other NZ based engineering companies and Crown Research organizations. The goal of this initiative was to connect the many niche engineering companies with China's Thorium reactor development to nurture a long-term partnership. The two parties agreed to a proposal and a three-day workshop with about thirty New Zealand engineers and fifty Chinese experts was planned for the next month. However, however four days prior to the NZ engineers leaving for China, one of the NZ Government organizations pulled out and sent a letter to all other members recommending they not participate in this 'nuclear venture' as it could have political impact. Though Matthew tried to explain that no fissile materials were involved in the initiative, the project was killed before it was formally launched.

When Matthew and a few loyal engineers met with the Shanghai Institute of Nuclear Applied Physics (SINAP) in October, the Chinese team of fifty were shocked that only four people from New Zealand had shown up. They were deeply offended and asked them to leave. It was one of the low points in Matthew's business journey.

2012 - November. Although not a nuclear physicist, Matthew was invited to present a paper to 200+ nuclear experts on his nuclear thermoelectric heat transfer concepts at the international Thorium Energy Conference in Shanghai, China. The short talk was well received and many future international opportunities and commercial partners seeded from the ideas he shared. It was also at this conference he met one of his future co-founders of Stargena.

2013 - 2014 The mega-projects partnership

Arvus developed a relationship with a US-based energy company to explore a joint venture for designing and implementing large infrastructure projects with a strong focus on humanities and clean-tech projects. Over the ensuing 24 months Arvus Global explored, proposed and applied for funding from various global funds for a number of significant projects including:

The role of Matthew and his Arvus team for all of these projects was to lead the technical teams and the company's overall project design. The plan was to move the Arvus Global leadership team (around 200 strong) to Cork, Ireland in early 2015 and to send teams on site on a regular basis. However, after two years the joint venture stalled in September 2014 and both parties agreed to go their separate ways.

2014 - In May Matthew presented a talk on commercialisation of technology at a Square Kilometer Array (SKA) conference and was introduced to a famed software evangelist. Their friendship grew over the following months and after the Arvus Global collapse they decide to start a software company together.

Arvus developed a relationship with a US-based energy company to explore a joint venture for designing and implementing large infrastructure projects with a strong focus on humanities and clean-tech projects. Over the ensuing 24 months Arvus Global explored, proposed and applied for funding from various global funds for a number of significant projects including:

- Japan - On Site Plasma-Arc Radiation Neutralisation (OSPARN) - This project was designed to neutralise the spent radioactive fuel rods at the Fukushima nuclear reactor site that had been exposed after the 2011 earthquake disaster. The design worked by super-heating the rods with experimental ultra-high temperature plasma reactors operating at over 25,000ºC. This process would convert them into usable inert building blocks, thus reducing the spread of nuclear waste. Project submitted but not funded.

- Canada - Tailing Ponds Clean up - This project aimed to use very efficient flare-gas reactors to filter & separate the highly contaminated tar sands ponds into sterile clean soil and to safely dispense of the cancer causing waste that was seeping into the water table affecting millions of people across Alaska, the US and Canada. Submitted but not funded.

- Caribbean Cleanup - This was by-far the most ambitious project at a planned span of 12 years. The scope included: three waste-to-energy plants, two water treatment plants, a light-rail system and a 1,500 bed world-class hospital able to withstand a category-5 hurricane. It also housed research facilities, vast storage for food, water and blood stores for the 500,000 people who lived in the path of the annual hurricanes. Submitted, funding awarded, but final agreement challenges adversely affected the project.

The role of Matthew and his Arvus team for all of these projects was to lead the technical teams and the company's overall project design. The plan was to move the Arvus Global leadership team (around 200 strong) to Cork, Ireland in early 2015 and to send teams on site on a regular basis. However, after two years the joint venture stalled in September 2014 and both parties agreed to go their separate ways.

2014 - In May Matthew presented a talk on commercialisation of technology at a Square Kilometer Array (SKA) conference and was introduced to a famed software evangelist. Their friendship grew over the following months and after the Arvus Global collapse they decide to start a software company together.

2015 - 2020 Nyriad

Nyriad became the first commercial spin-out of the SKA and was Matthew's total focus as CEO. The software company was originally based in Cambridge, New Zealand. The technology utilised CPUs and GPUs for significant improvements in large scale data storage arrays. Over the next five years Nyriad raised dozens-of-millions in venture funding from investors in New Zealand, Australia, Japan, South Africa, Europe and USA while hiring and training many young local software engineers.

Nyriad became the first commercial spin-out of the SKA and was Matthew's total focus as CEO. The software company was originally based in Cambridge, New Zealand. The technology utilised CPUs and GPUs for significant improvements in large scale data storage arrays. Over the next five years Nyriad raised dozens-of-millions in venture funding from investors in New Zealand, Australia, Japan, South Africa, Europe and USA while hiring and training many young local software engineers.

2020 - With Covid-19 impacting the international business landscape, Matthew and his Nyriad board agree that the company should move closer to the IT industry in the US and hire a new executive team to scale the company to the next level. During this period Matthew began to sense a need to re-enter the audio industry, plus he also had a strong desire to pursue his passion for energy and space. In October, while keeping all of his equity in the company which he proudly co-founded he resigned as CEO & stepped off the Board.

The following month Matthew began investing resources into developing what would become the H2-4D digital audio converter. As he had been away from the audio industry for almost 6 years, he also undertook a great amount of market research into its current state.

2020 - In December, after almost two years of extensive research of the Space sector, Matthew co-founded Stargena in the US with some atomic industry colleagues, with a focus on developing power systems for deep space robotic missions. The technology is advanced and complex. The company has a board and engineering team in place. Stargena expects to be in stealth-mode for a few years.

The following month Matthew began investing resources into developing what would become the H2-4D digital audio converter. As he had been away from the audio industry for almost 6 years, he also undertook a great amount of market research into its current state.

2020 - In December, after almost two years of extensive research of the Space sector, Matthew co-founded Stargena in the US with some atomic industry colleagues, with a focus on developing power systems for deep space robotic missions. The technology is advanced and complex. The company has a board and engineering team in place. Stargena expects to be in stealth-mode for a few years.

2021 and Beyond... The next exciting Arvus chapter

2021 - After a year of market research and technical exploration plus an injection of capital, Arvus International Limited is set up. A full business plan and product strategy is defined, and H2-4D development is completed in August. The first order sold out two weeks after its product launch in September.

2022 - Arvus.com goes online Feb 1st, beta units of H2-4D shipped in March.

2022 - October, hundreds of the first full production run of H2-4D are shipped and the company expands its team with the Arvus Advisors joining the company.

2022 - November, development of a smaller model called the H1-D (HDMI to AoIP, Dante etc.) is started.

2023 - H1-D development accelerates with a Beta launch date set for September '23

2021 - After a year of market research and technical exploration plus an injection of capital, Arvus International Limited is set up. A full business plan and product strategy is defined, and H2-4D development is completed in August. The first order sold out two weeks after its product launch in September.

2022 - Arvus.com goes online Feb 1st, beta units of H2-4D shipped in March.

2022 - October, hundreds of the first full production run of H2-4D are shipped and the company expands its team with the Arvus Advisors joining the company.

2022 - November, development of a smaller model called the H1-D (HDMI to AoIP, Dante etc.) is started.

2023 - H1-D development accelerates with a Beta launch date set for September '23

Matthew A. Simmons

CEO / Founder

arvus.me (Matthew's personal linktree to his other projects / ventures)

CEO / Founder

arvus.me (Matthew's personal linktree to his other projects / ventures)